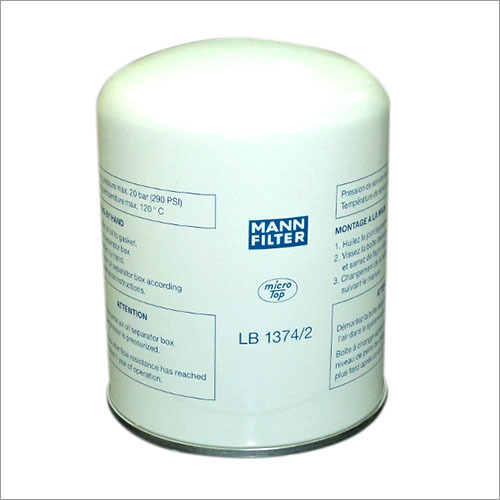

Compressor Oil Filters

Compressor Oil Filters Specification

- Flow Rate

- Up to 180 l/min

- Capacity

- Designed for compressor oil systems up to 100 HP

- Media Type

- Synthetic fiber/cellulose

- Temperature Range

- -25C to +120C

- Efficiency (%)

- 99%

- Filter Type

- Oil Filter

- Connecting Type

- Threaded/bolt-on

- Pressure

- Up to 12 bar

- Filtration Grade

- Fine

- Cleaning Method

- Replaceable (not cleanable)

- Condition

- New

- Material

- Metal housing with cellulose or synthetic filter media

- Mesh

- Fine filtration mesh up to 25 micron

- Diameter

- Custom sizes available (standard: 80-150 mm)

- Construction

- Seamless welded body with threaded or bolt-on fittings

- Medium Filter

- Oil

- Weight

- Approx. 500-1200 grams depending on size

- Shape

- Cylindrical

- Feature

- High filtration efficiency, durable construction, corrosion-resistant

- End Cap Type

- Metal/plastic

- Application

- Used for removing contaminants from compressor oil

- Compatibility

- Suitable for rotary screw, reciprocating, and centrifugal compressors

- Surface Finish

- Powder coated/painted

- Seal Type

- NBR or FKM rubber gasket

- Mounting Type

- Vertical/horizontal

- Bypass Valve

- Integrated (optional)

- ISO Certification

- ISO 9001:2015 approved

- Service Life

- 2000-4000 operating hours

- Color

- White, Black, Custom

Compressor Oil Filters Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3000 Units Per Month

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- carton boxes

- Main Domestic Market

- All India

About Compressor Oil Filters

Established in 1999, we are a New Delhi based company engaged in manufacturing and exporting top notch quality range of Compressor Oil Filters. These are widely used in automobile and various oil based industries to remove dirt or filth from oil. Dirty oil is very bad for machinery and equipment as it can jam and slow down the processing. These filters are precisely manufactured at our state-of-the-art facility using quality tested raw materials and pioneering technology. We offer Compressor Oil Filters in different models and technical specifications as per requirements.

Features:

-

Available in application specific designs

-

Sturdy build quality

-

Efficient and reliable performance for a long time

High Filtration Efficiency and Endurance

Experience superior contaminant removal with our compressor oil filters, specially engineered to capture particles as fine as 25 microns. The robust construction features seamless metal housing and synthetic fiber or cellulose media, ensuring over 99% filtration efficiency and durability throughout demanding operations. Powder-coated finishes safeguard against corrosion and wear, extending filter life.

Versatile Compatibility and Installation

These filters support rotary screw, reciprocating, and centrifugal compressors, making them ideal for multiple industrial setups. With vertical or horizontal mounting, various end cap types, and options for threaded or bolt-on connections, installation is straightforward. Custom diameters and colors accommodate specific application needs, enhancing operational flexibility.

Reliable Performance and Certification

Designed for compressor oil systems up to 100 HP and pressures up to 12 bar, these filters maintain reliable oil flow at up to 180 l/min. The NBR or FKM gasket seals perform well from -25C to +120C. ISO 9001:2015 certification assures quality, while replaceable filter elements simplify maintenance for dealers, distributors, or direct users in India.

FAQs of Compressor Oil Filters:

Q: How does a compressor oil filter improve compressor performance?

A: A compressor oil filter removes dirt, metal shavings, and other contaminants from compressor oil, which enhances lubrication, reduces wear, and extends compressor lifespan. Its high filtration efficiency (99%) ensures the oil stays clean, resulting in optimal and reliable compressor performance.Q: What types of compressors are compatible with these oil filters?

A: These oil filters are suitable for rotary screw, reciprocating, and centrifugal compressors, making them versatile for various industrial applications. The adaptable mounting and connection options allow seamless integration across different compressor models.Q: When should the compressor oil filter be replaced?

A: It is recommended to replace the oil filter after 2,000 to 4,000 operating hours, depending on application severity and oil quality. Regular replacement maintains filtration efficiency and prevents potential compressor damage caused by contaminated oil.Q: Where can I mount these compressor oil filters?

A: Filters can be mounted either vertically or horizontally, depending on your compressor systems configuration. The seamless welded body and threaded or bolt-on fittings ensure secure installation in a range of industrial environments.Q: What is the cleaning process for compressor oil filters?

A: These oil filters are designed as replaceable components and are not cleanable. When the filter reaches the end of its service life, simply remove and replace it with a new filter to maintain consistent filtration and compressor protection.Q: What are the benefits of using a fine mesh filter media in compressor oil filters?

A: Fine mesh filter media, made of synthetic fiber or cellulose, provides filtration down to 25 microns. This high level of filtration captures small particles, greatly reducing oil contamination and enhancing compressor reliability and service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oil Filters Category

Industrial Oil Filters

Price Range 500.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Cleaning Method : Other, Replaceable / Disposable

Filtration Grade : Other, Industrial, PreFilter & Fine Filtration

Material : Stainless Steel, Filter Paper, Metal End Caps

Pressure : Up to 16 Bar

Compressed Oil Filters

Price Range 500.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Cleaning Method : Other, Washable/Replaceable

Filtration Grade : Other, High Efficiency

Material : Stainless Steel, Mild Steel, Aluminum

Pressure : Up to 16 bar

Air Oil separators

Price Range 500.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Cleaning Method : Other, Nonwashable, Replaceable cartridge

Filtration Grade : Other, Fine Filtration

Material : Stainless Steel, Aluminum, Glass Fiber

Pressure : Up to 16 Bar

Air Oil Filters

Price Range 500.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Cleaning Method : Other, Replaceable / Nonwashable

Filtration Grade : Other, ISO 16889 / equivalent

Material : Stainless Steel, Aluminum, Synthetic Fiber

Pressure : Max. 20 bar

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS